Ideal Stoves

Installation Pack A

Installation Pack A

Couldn't load pickup availability

Installation Pack "A" includes:

- Pack No. 3, Pot Hanging cowl installation kit with 125mm flex adaptor

- Multi-fuel flexible liner

- Rigid fixed 500mm pipe

- Register Plates

- CO Alarm

DETAILS

Pack No. 3, Pot Hanging cowl installation kit with 125mm flex adaptor

Overview

MF20 MI-FLEX Accessories is a family of installation fittings that have been perfectly designed for use with MI-FLEX 316 and 904 flexible flue liners. When fitted in conjunction together It will make a full system chimney.

General Application

These items are to be used in conjunction with MI-FLEX multi-fuel flexible flue liner. Building Regulations Document J requires that a flexible flue liner can only be installed completely enclosed inside a masonry chimney. A non-masonry enclosure such as timber or plasterboard boxing-in is not acceptable. All items are suitable for use on appliances up to 600°C (T600 designation). Suitable for use on Wood <20% moisture, Smokeless coal, Gas and oil.

Installation kits

Installation kits are a complete package designed to give you all you need to install a flue liner in a specific scenario. MI-FLEX is not included.

Specific Application

Use this pack when you DO NOT want to remove the existing chimney pot.

1 x Stainless Steel Pot Hanging Cowl with Mesh - Ø 125mm

1 x Nose Cone - Ø 125mm

1 x Adaptor to Black Pipe or Single Wall Flue - Ø 125mm

1 x Chimney Notice Plate

Maintenance

The chimney system must be designed to allow for easy provision for sweeping and maintenance. Sweeping must be carried out by competent person. On solid fuel applications, a list of HETAS registered sweeps can be found at www.hetas.co.uk. under no circumstances should chemical cleaners or mild steel tools be used to sweep stainless steel chimneys. Cleaning and inspection of the chimney system should be carried out at least once a year, along with maintenance of the appliance, but it is recommended that chimneys serving solid fuel appliances be swept at least twice a year, at the end of the heating season to remove any deposits, which may have built up during the season, and at the start of the next heating season to check for any blockages or deposits. I.e. bird nets.

Product Details

| SKU | 20-125-P503 |

| Item | Installation Pack No 503 - Ø 125 |

| Designation: | BSEN 1856-2 T600 N1 W V2 L50012 G |

| System: | MI-FLEX Accessories MF20 |

| Material: | 316L |

| Colour Finish: | Natural / Stainless Steel |

| Fuels: | Wood, Oil, Gas, Smokeless coal |

| Approvals: | HETAS / CE |

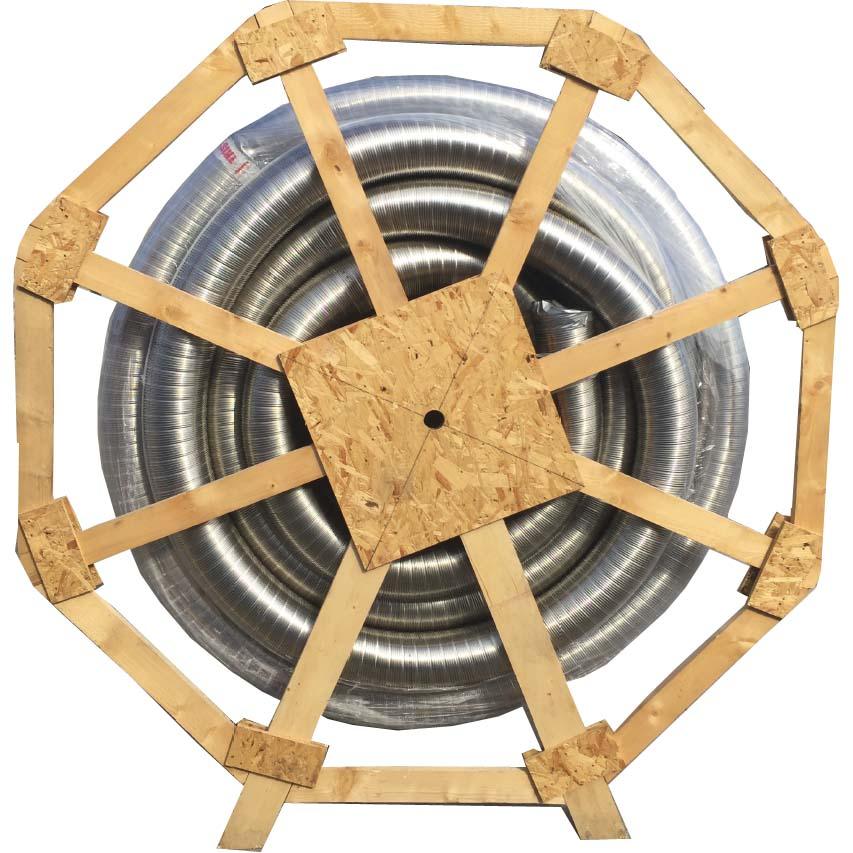

Multi-fuel flexible liner made from 316L grade stainless steel

This product carries a Lifetime manufacturer's warranty when installed with Screw-FIX accessories.

APPLICATION

A double skinned flexible flue liner suitable for relining within a masonry chimney. Flue liner is suitable for use with burning gas, oil, coal, coke, cured dry logs, cured dry peat.

CONSTRUCTION

The flue liner has a smooth inner liner made from 316L grade stainless steel and is 0.105mm thick. The flue liner has a convoluted outer skin made from 316L stainless steel and is 0.105mm thick. The Flue Liner is constructed from a single strip of steel which is bent at 180 degrees and then the seam is folded in four planes to give a Omega-Lock seal.

APPROVAL

Flue Liner is approved and listed by HETAS it is also CE approved

INSTALLATION - CHECK LIST

1.Make sure the liner will go down the chimney (this can be done by pulling down a small section of the diameter liner you will be using)

2.Sweep your chimney.

3.Check you pot is in good condition, if you are NOT using a suspended cowl then remove the pot from the stack.

INSTALLATION

Flue Liner should always be fitted from the top.

Make sure the arrows are pointing upwards (gas flow).

Secure a piece of string (at least the same length as the Flue Liner to the Nose Cone (order separately).

Now attach the Nose Cone onto the end of the Flue Liner, again making sure the arrows on the Flue Liner are pointing away from the Nose Cone in a upward direction so when the liner is installed the arrows will be pointing to the top of the chimney

Pull the liner down the chimney using the string and at the same time have someone at the top of the chimney feeding the Flue Liner down, once the Flue Liner is fitted remove the Nose Cone.

MAINTENANCE

It is recommended that chimneys serving solid fuel appliances be swept and maintained as frequently as necessary but at least once a year.

Product Details

| SKU | 35Z-125-1 |

| Item | 316L Mi-FLEX 125mm x 1m CUT LENGTH 125mm (5 inch) |

| Designation: | BS EN 1856-2 T600 N1 W Vm L50011 G |

| Designation: | BS EN 1856-2 T200 P2 W Vm L50011 O |

| Inner Material: | 316L - 0.105mm thick |

| Outer Material: | 316L - 0.105mm thick |

| Fuels: | Wood, Oil, Gas, Low sulpher coal |

| Approvals: | HETAS |

| Manufacturer: | Mi-Flues Ltd |

| Manufacture: | Single Strip |

| Seam: | Omega-Lock |

| Warranty: | Lifetime |

Rigid fixed 500mm pipe effective installed length of 445mm

APPLICATION

Suitable for gas, oil and solid fuel appliances with temperatures up to 600°.

VIT-Smooth pipe should only be used as a connecting pipe between your appliance and Flue Liner / Chimney Stack / Twin Wall Flue System.

VIT-Smooth pipe should NOT be used to pass through ceilings or combustible walls.°

CONSTRUCTION

VIT-Smooth is a single skin connecting flue system manufactured in zero carbon steel with Powder vitreous enamel coating in a matt black finish.

Suitable for gas, oil and solid fuel appliances with temperatures up to 600°.

INSTALLATION

You should not install a piece of VIT-Smooth 100mm within 375mm from combustible material, e.g. wood, plaster boards, etc.

When installing make sure VIT-Smooth is installed the correct way up - the smaller diameter should always be pointing downward.

This is because all the condensates will stay within the flue system and not pass to the outside of the VIT-Smooth.

VIT-Smooth is a friction fit joint so dose not require sealing of the joints, For extra security if desired each joint could be coated with a jointing compound (fire cement or high temperature silicone sealant).This makes sure that no condensate can escape and spoil the appearance of the pipe.

VIT-Smooth has been designed to be cut, but care must be taken to cover any exposed steel with high tempteture paint as this will rust over time.

When installing appropriate PPE should be worn at all times.

MAINTENANCE

You should make provision for inspecting and cleaning the chimney. This is particularly important on solid fuel applications.

You can acheive this by installing a VIT-Smooth with an access doors at changes of direction.

It is recommended that chimneys serving solid fuel appliances be swept and maintained as frequently as necessary but at least once a year.

Product Details

| SKU | 67-125-011 |

| Item | 500mm Pipe - Ø 125mm |

| Material: | Zero Carbon Steel |

| Steel Thickness: | 1.2mm |

| Coating: | Powder Enamel |

| Coating Thickness: | 0.2mm |

| Colour: | Black |

| Approval: | EN1856-2 T600 N1 Vm L80120 G375 |

| Distance to combustible: | 375mm |

| Diameter: | 125mm |

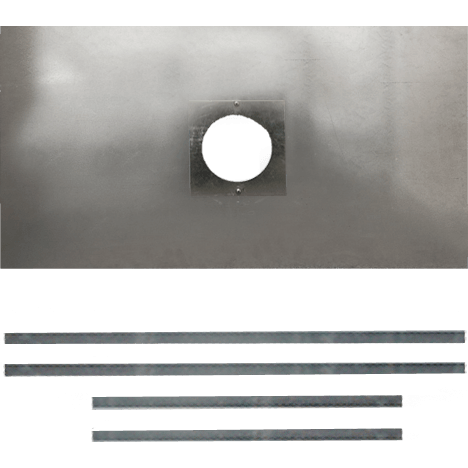

Register Plates

Register Plates are used to seal off the base of the chimney.

This Register Plate is 900mm x 600mm

It is suitable for 180mm and 200mm (7 and 8 inch) Black Stove Pipe.

USE THIS REGISTER PLATE WHEN VERMICULITE IS TO BE USED TO INSULATE THE FLUE.

APPLICATION

Use to seal off the base of the chimney (This Register Plate can be cut on site to fit the base size of your chimney stack). The Register Plate will support vermiculite and stop any debris from within the chimney stack coming down the chimney and hitting your stove.

CONSTRUCTION

The Register Plate and the Supporting Brackets are made from 1.5mm thick galvanised steel. The Register Plate can be sprayed to match the colour of your stove pipe. This Register Plate has a special adaptor suitable for installations which use either 180mm or 200mm diameter flue pipes.

INSTALLATION

The four supporting brackets should be cut to the length and width of the base of your chimney stack. Drill a number of holes in the brackets. Now screw them into the brickwork. Cut the Register Plate to the correct size, taking care that the pipe hole lies vertically above the Black Stove Pipe. Drop the Register Plate onto the supporting brackets. Now seal any gaps between the brickwork and the brackets / plate using Fire Cement or High Temperature Sealant. For 150mm diameter installations simply remove the centre cover ring by unscrewing the two retaining screws.

MAINTENANCE

It is recommended that chimneys serving solid fuel appliances be swept and maintained as frequently as necessary but at least once a year. At the same time remove the Register Plates inspection hole cover plate(s) and hoover / sweep any debris that has fallen.

DO NOT REMOVE COVER PLATES IF VERMICULITE HAS BEEN INSTALLED AS ADDED INSULATION.

Product Details

| SKU | 94-REG-J |

| Item | Register Plate (J) - 900x600 no access hole - Ø 175 200 |

| Material: | Galvanised Steel |

| Thickness: | 1.5mm |

| Fixing Angles: | 4 |

| Length: | 900mm |

| Width | 600mm |

| Hole Diameter: | 180/200mm |

| No of Cleaning Holes: | 0 |

| Suitable for Insulation: | Yes |

CO Alarm - Firehawk CO7B

The FireHawk CO7 battery-operated Carbon Monoxide alarm is ideal for the home. Its compact size takes up little room gives you invaluable protection from faulty heating and cooking appliances wherever you are.

Sealed-in Lifetime Lithium Battery

Long Life Sensor. Top quality Figaro electro-chemical sensor ensures accuracy and longevity

POSITIONING

The position of the alarm should be where it can detect CO as soon as possible to alert and protect the occupants of the premises. Make sure it can be heard by the occupants when in all parts of the premises. DO NOT place closer then 1 metre from the source appliance.

PLEASE NOTE: If either or both of these conditions cannot be met, additional alarms should be fitted throughout the premises.

USEFUL INFORMATION

REMEMBER - The overriding instruction is to ALWAYS follow the manufacturers guidance

Place the alarm in the room of potential origin of CO.

Place it high in the room (Above the tops of windows and doors) but no closer than 150mm from the ceiling.

If the alarm is in another room and NOT the room of origin it should be placed within the breathing zone of occupants in the room.

Be particularly aware of the elderly, disabled and children; and their limitations.

TEST THE ALARM BEFORE LEAVING THE PREMISES CARBON MONOXIDE IS HOT WHEN IT IS RELEASED SO IT WILL BE CARRIED UPWARDS TO THE TOP OF THE ROOM OF ORIGIN FROM WHERE IT WILL COOL AND FALL TO ALL PARTS OF THE PREMISES.

REMEMBER - The overriding instruction is to ALWAYS follow the manufacturers guidance.

Test the alarm once a week to ensure it is still operating. ONLY use the test button.

Vacuum the alarm to keep the vents clear of dust and insects.

Every six months clean the alarm with a damp cloth (do not use spray or chemical cleaners and polishes).

In the event of a problem, read the handbook and/or contact the manufacturer.

Replace the alarm at the end of its life.

Product Details

| SKU | 13-CO-7B |

| Item | CO Alarm - Firehawk CO7B CO Alarm - Firehawk CO7B |

| Weight: | 0.084 kg |

| Dimensions: | 3 × 6.5 × 10 cm |

| Warranty: | 7 Years |

| Approvals: | BS EN 50291 1:2010+A1:2012 BS EN 50291-2:2010 |

Share